Market

sectors

Expertise to serve

many industries

Our technology and capabilities provide value driven solutions

to a variety of industries.

Powersports

Powersports is a market where we can find many blow molded parts such as fuel tanks, coolant tanks and air ducts, to name a few. Lefko is an expert in delivering technically challenging parts.

Transport

The transport industry is changing quickly and blow molding can efficiently fill the market’s evolving needs.

Blow molding ranks among the most economical molding processes of mass-produced plastic parts. The equipment costs are low and the cost per part is very advantageous compared to other processes such as rotational molding and thermoforming, whose parts cost significantly more.

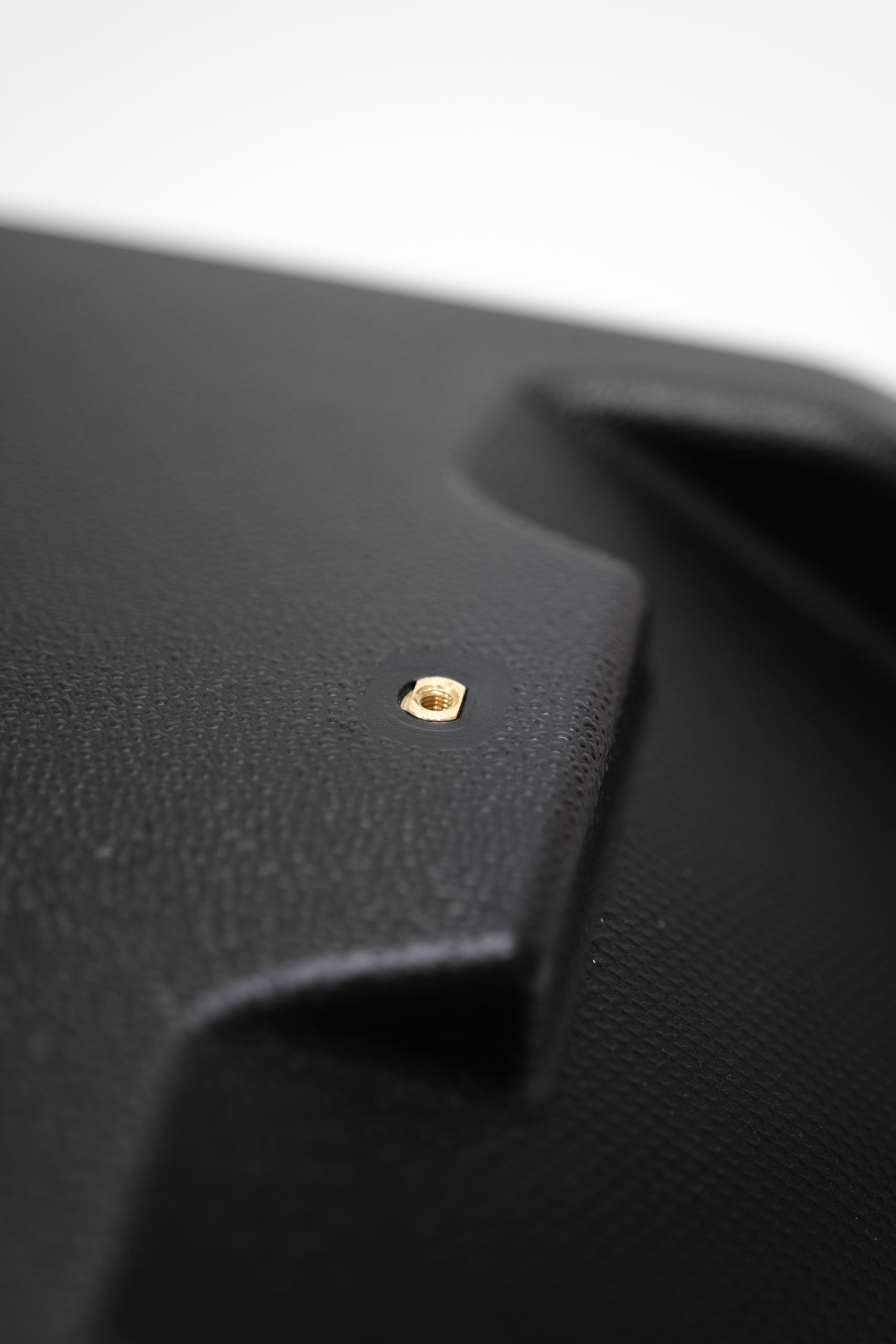

Industrial

In the industrial sector several metal objects have been substituted for plastic objects thanks to blow-molding technology.

Due to its inherent mechanical structure and its versatile shape, the blow-molding product is often selected to substitute what was formerly made of several parts.

Blow-molded parts can meet fire standards often required in industrial or building products. We are familiar with the UL (Underwriters Laboratories) standards and RoHS because many of our customers need to abide by them.

Medical

Lefko has acquired a high level of knowledge about the specifics and standards for medical products. Lefko can offer the possibility to have a smooth surface finish without asperities, allowing an easy cleaning which is essential in this industry.

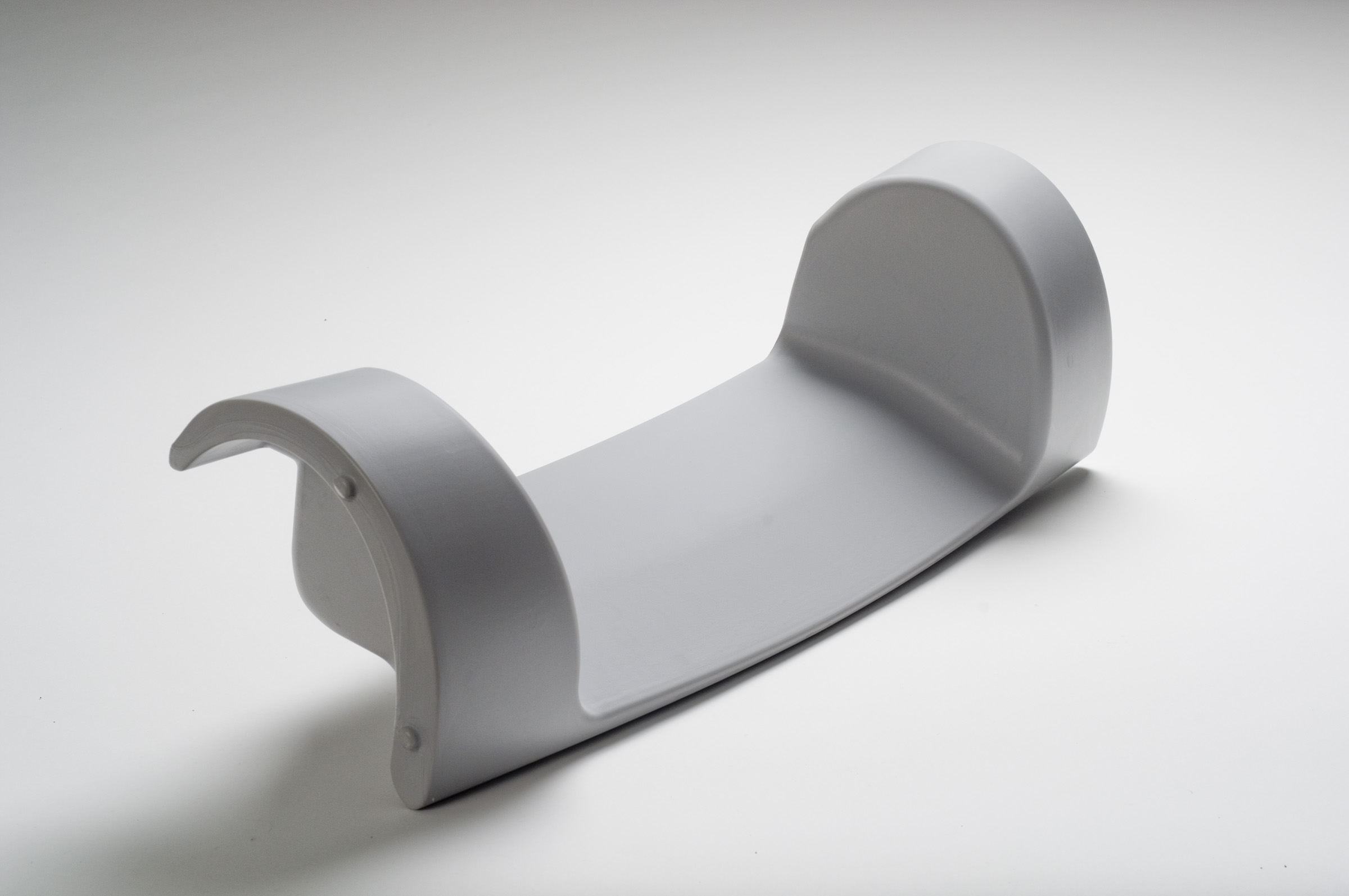

Recreational

Having developed several products for this industry, Lefko has acquired expertise in understanding its different needs. With its ongoing enhancement approach, Lefko can make innovative suggestions that greatly benefit its customers.